The Following is an update composed for the engineers working on the QEG written by James Robitaille. It can be found for comments and discussion at the following link on the be-do.com website link here:

Please Help us spread this valuable knowledge to all of those who are helping us co-develop the QEG.

QEG Synopsis: 5-Feb-15

Update – Present Stage of QEG Development, Latest Findings, & Call for Experiments

From: James Robitaille / FTW HQ, Morocco

There is some detailed engineering included in the original document released in March of 2014, but as you know, there were a few mistakes and unintentional omissions. We’re in the process of updating the manual, as there is much new information since the original release. We’ve had at least 15 groups build the machine and successfully get to the point of resonance and producing power using only that original document. However, until the manual update is completed, all the latest information is currently being presented only in the ongoing QEG 101 course. In order to keep everyone informed of the latest progress, we are posting this document here on the be-do website forum.

We’ve successfully built 5 machines ourselves, and have confirmation of reaching resonance from at least 10 other builders around the world. At the present point in development, the machine will produce a maximum of about 800 Watts output, for input of about 1,000 Watts. So we’re still 200 Watts away from unity (input and output at same level).

When I say “reaching resonance”, this is the 1st level (basic resonance) of 3 levels of resonance we’ll need to reach before the machine will run itself, and produce usable output to power loads. The most recent work (December, 2014) was targeted at experimenting with methods to obtain the other 2 resonances, and we expect to reach that point before the end of the 10 week QEG course, but we need your help.

The remaining 2 resonances involve using the core’s mechanical resonant frequency to produce additional potential (voltage) through the piezoelectric effect (2nd resonance), and then using the exciter coil (which is a type of antenna) to establish the 3rd resonance which brings in further energy from the surrounding environment to ‘electrify’ the QEG core (this is the “quantum energy” the QEG’s name refers to).

The machine was originally designed in the 1930’s when modern electronics were not available, and electronics are not needed to generate output power well in excess of the input power used to run the motor and spin the rotor. Electronics are needed only for the frequency conversion (400Hz to 50/60Hz), and output voltage regulation (120/240 VAC). We have several different electronic (and some electromagnetic) solutions that can be applied once we reach that point in development, and of course we’ll use the most efficient method.

When the machine is running and generating output, the primary voltage is produced by Parametric Oscillation (primary tank circuit reluctance/inductance modulated by the rotor motion). This is the source of power in the QEG, and power is transferred to the secondary windings at the zero crossing points, so there is no stall effect (very little back EMF/Lenz effect), and very little heating of the core/windings. These are some of the unique features of this generator.

Latest Findings from Experiments in Florida

The recent experiments done in Florida, USA showed some promising results. However, we had to stop working to pack up the lab and make the move here to Morocco before we could further evaluate the results. The lab equipment is en route to us here in Morocco, but we’re not sure how soon it will arrive. So, rather than waiting for us to resume work after setting up the Morocco lab, then releasing our findings to all the groups and individuals with working QEGs (or close to that point), we want to ask you, the QEG builders, experimenters, and students, to try the following experiments, and help us all get to the next stages of completion.

A technical description of the previous experiments and next steps we want to try is outlined below.

2nd RESONANCE – CORE MECHANICAL RESONANCE

A method was needed to characterize the frequency response of the wound core, in order to determine the frequency (or range of frequencies) where the core steel will ‘ring’ or self-resonate. This ‘ringing’ produces vibration which builds voltage in the core, providing an exponential increase in the power available from both the primary and secondary windings, through the piezoelectric effect. This effect is independent of (and additive to) the power produced by the basic parametric oscillation (basic resonance).

Our first attempt to find this frequency was to use a VFD (variable frequency drive) for an AC motor, driving a variac, to create a continuously variable voltage and frequency signal of 0-120VAC @ 47-450Hz. The plan was to simulate the QEG operating in resonance throughout the entire frequency range between 47-450Hz (720 to 6,750 RPM), without actually spinning the rotor, or switching resonance capacitors in and out. This continuously variable (sweep) signal was then coupled to a 9,000V neon sign transformer, with output connected to the QEG primaries (to simulate the actual QEG primary voltage) – See schematic here:

File Attachment:

File Name: QEGcorefreqsweepsetup.pdf

File Size: 15 KB

We then connected a scope across the secondary windings, to look for resonance peaks while manually sweeping the input (primary) frequency. The results of the test were inconclusive due to the neon sign transformer’s limited output current (only 30mA). This proved to be insufficient power to drive the core. However, this led us to a modification of the test, which did prove successful.

A 600 Watt automotive audio power amplifier (with 12VDC switching power supply) was employed this time, to drive the low impedance (approx. 1.5Ω) secondaries, wired in series. We used a 20MHz signal/function generator to drive the audio amp with a 50% duty cycle square wave signal, between about 47Hz and 2,000Hz (2kHz). We then connected the scope across the primary windings (also wired in series) and observed the core’s response to the input signals. The output level from the signal generator was set to about 18V, just below clipping of the signal, and the rotor was held stationary, in alignment with 2 of the pole pieces (for maximum inductance) – See schematic here:

File Attachment:

File Name: QEGcoremechanicalresonancesweepsetup.pdf

File Size: 14 KB

The test was done with no load (resistance) across the primaries, in order that all aspects of the signal could be observed, including reflections and harmonics. The results provided several of the answers we’ve been looking for, both directly and by inference;

1. The input square wave converted to a sine wave at the output (this is a known but interesting effect when working with inductors, and is effective for determining harmonic content).

2. As we swept through the frequency range, there was a very obvious fundamental resonance just around 1,500Hz (1.5khz). The input voltage to the secondary windings at this frequency was amplified by more than a factor of 30 at the output! We tested 2 different cores (one with epoxy impregnation, one without), and the fundamental was between 1,560Hz and 1,630Hz, depending on the rotor position. We also have one class participant that tested an unmounted bare stator (before winding) that reported reading 1,135Hz simply by tapping the steel with a small hammer. This is also close enough to confirm the test results, since the rotor, windings, spacer blocks, and mounting surfaces were not involved in the bare stator test. Because of mechanical limits, a practical maximum RPM for this machine would only be slightly over 3,000 RPM (200Hz). So we can’t actually spin the rotor fast enough to output 1,500Hz directly. That would require a speed of something like 22,500 RPM. So obviously we have to run on a harmonic of 1,500Hz.

3. Carefully dialing down the frequency from 1,500Hz, we observed several harmonics that still had plenty of amplitude to excite the steel core. The first appeared around 730Hz, then 406Hz, 201Hz, and around 122Hz. The 406Hz and 201Hz harmonics are right on the frequencies Witts told us would produce the desired core steel resonance. It’s important to note that the fundamental resonance appears on the scope as a huge single peak, the 1st harmonic as 2 peaks, the 2nd as 3 peaks and so on. Upon zooming out with the scope, we saw that the harmonics are actually the peaks of a ‘ringing’ waveform. This is a clear indication that the signal is reflecting (off the steel) at these harmonic frequencies, which is what we’re after.

4. The next step is to focus on the harmonic with the most amplitude that is within the practical speed range of the generator. We are told by Witts that this should be right around 400Hz, but for the generator to run at this frequency would require RPM to be around 6,000. This is too fast for the mechanical setup. Even 3,000 RPM is a bit high, although it could be used. We know that the Witts generator we see in the “Self-Running 40kW Fuelless Generator” video is running at 2,450 RPM, which is right in the mechanical “sweet spot”. With all these considerations in mind, it becomes clear that what we need to do is double the generator output frequency, but without doubling the rotor speed. That’s where the following experiments come in.

CALL TO OUR PROJECT SUPPORTERS TO PERFORM EXPERIMENTS – ADDITIONAL FEEDBACK COILS

To those of you who have reached resonance (or are close), we propose to add feedback coils on top of both secondary coils, in an experiment to transfer energy back and forth between the primary and secondary windings. With reference to Tesla’s work, we would expect to see several effects realized:

1. Since the energy stored in the resonant LC tank circuit is normally supplied to the output coils (and load) during the period when the rotor is between poles (primary voltage at zero crossing), we see a path where the addition of feedback coils will serve to transfer energy (real power) back to the primary during the output interval, effectively inducing a second voltage peak halfway between the normal primary voltage peaks (remember that the output frequency is 2X the resonant tank frequency). This (50% displaced) second voltage peak would not be due to the (resonant) modulation of the primary inductance, rather it would be real power, fed back during the secondary’s output cycle. We think one likely result of this modification would be a doubling of the generator frequency, without the corresponding increase in rotor speed. With some fine tuning, this should allow excitation of the core steel at the harmonic residing near 400Hz, while still running at a practical RPM.

2. The additional small wire coils (probably 20 gauge) wound over the secondaries are fairly obvious in the Witts videos. With the resonant tank capacitor value based on rotor RPM (parametric pumping frequency), and the inductance value of the primary windings, this proposed modification will effectively lengthen the wire in the primary windings (feedback coils in series with primary). This could explain why the resonance capacitors in the Witts video are apparently too few and too small to be the corresponding value for the running RPM (2,450 RPM, about 163Hz). It follows that the increase in wire length will increase inductance and therefore less capacitance would be required for the same RPM.

3. Other desirable effects will almost certainly be seen, but would be difficult to predict without actually performing the experiment. So here are the details of how we would proceed.

EXPERIMENT DETAILS:

The experiment may be easier to do on a core without epoxy since there will be more room between the secondary coils and the endplates, although it can still be done on either style to prove the concept.

• Unmount the core and remove rotor. Support the core on a strong work surface with clear space around the existing secondary windings.

• If you have a core without epoxy, we would recommend wrapping 2 layers of mica tape or Kapton tape over the existing white fiberglass outer wrap for additional insulation, since the new coils will be carrying the primary high voltage. If you have an epoxied core, no additional insulation should be necessary, although it may be easier to wind the wire if a layer of fiberglass tape is installed just so the wire won’t slide around on the smooth epoxy surface.

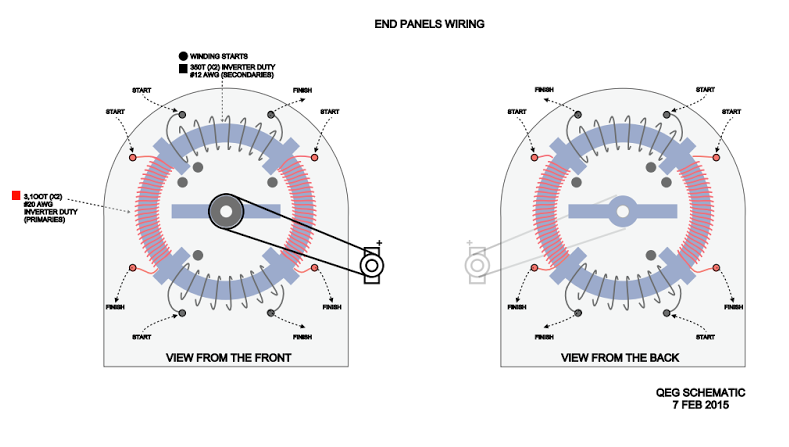

• Using the same 20 gauge (inverter duty) wire used to wind the primaries, begin winding against the same pole piece where the existing secondary winding starts, and wind in the same direction as the secondary coils. Wind across the entire surface as evenly as possible, from pole piece to pole piece (cover entire secondary winding) – See attached schematic here:

File Attachment:

File Name: AdditionalCoilSetupv1.pdf

File Size: 38 KB

• The optimum number of turns will have to be determined experimentally. We would start with 350 turns per winding (same as secondary number of turns), but this could be reduced (or increased) depending on how much space you have. The turns count should be the same for both coils in any case, to keep the system balanced.

• Connecting the new coils to the existing primary windings will also have to be determined experimentally. There are several possible configurations depending on phasing, bucking and non-bucking etc. We would start by connecting according to the attached schematics, which place one end of each of the new windings in series with the capacitor connected ends of each of the existing primaries, then connecting the remaining ends (of the new windings) to the resonance capacitors (extend each existing primary coil). It’s also possible that the existing midpoint connection on the primaries (the 2 START leads connected together) could be opened, and the new coils inserted in series at that point. If done this way, also connect the 2 start leads of the new coils together, with END leads to START leads of existing primaries. The proper connections will become evident after testing the possible combinations – See attached schematic here:

File Attachment:

File Name: QEGoriginalsetupw-feedback_xp.pdf

File Size: 14 KB

CONCLUSION

Please interact with other engineers, builders, and experimenters, and let us know your results, questions, problems, observations, etc., and we will move this along!

Most Importantly, Have Fun! We’re here for you.

Many Thanks and Blessings!

James & the Fix the World/QEG Team

James & the Fix the World/QEG Team

Present Stage Of QEG Development, Latest Findings and Call For Experiments

On this weeks free energy show Hope, James Robitaille and Tivon Rivers discuss an important update posted to the Be-do.com website explaining the latest promising experimental findings for the next stage of QEG completion. This information is an exercise in co-development for all those who are building QEG’s. James and Tivon discuss the latest QEG synopsis which involves instructions for additional coil windings and accompanying schematics.

Also discussed is a full overview of our successful QEG Beginners Build Classes that are now in session.

Watch the Show for Free on Fix the World TV Here: http://fixtheworld.podbean.com/e/episode-7-qeg-synopsis-latest-findings-call-for-experiments/?token=a7067a7fc890db09fccbded530659e86

Related show links:

Working QEG video showing additional coil analyzed in the show:

Beginners Build Courses:

No comments:

Post a Comment